Product Description:

Brief Introduction:

This equipment uses ceramic anilox roller for polishing, with uniform coating, long service life of the coating roller,

bright and lustrous printing quality. Especially suitable for large

and medium-sized printing plants, which can steadily reduce

production costs and improve production efficiency for customer

enterprises.

Features:

It can both local and overall coating, and has the advantages of high working speed, high gloss, thin and uniform coating layer. It is widely used in packaging decoration, book cover and other

printing materials.

Application:

1. Spot coating, you can choose to coating one or more patterns on

the surface of the paper. After coating, the pattern will be more

three-dimensional and have better texture, which can make the

pattern more prominent and eye-catching.

2. Full coating gives the paper a thin protective layer on all

sides, making the product wear-resistant, stain-resistant,

waterproof and dust-proof, allowing the product to be used longer.

Specification:

| Model | Ecoo coating-760 |

| Max.sheet size | 760x595mm |

| MIN.sheet size | 290X270mm |

| Sheet weight | 80-400gsm |

| Production speed | 6000 sheet/h |

| Power | 45kw |

| UV lamp | 3 pcs x 8 kw |

| IR lamp | 18 pcs x 1 kw |

| Paper feed heigh | 1050mm |

| Paper stack height | 920mm |

| Weight | 65000kg |

| Dimension | 9500x2050x2000mm |

The whole machine has a one-key acceleration function. After the

main machine accelerates, the oven, paper delivery, feeder, and

metering roller will all change according to the speed of the main

machine.

1: Adopt high-speed offset press feeder to ensure fast and stable

operation

2: Equipped with non-stop paper feeding device to ensure continuous

production.

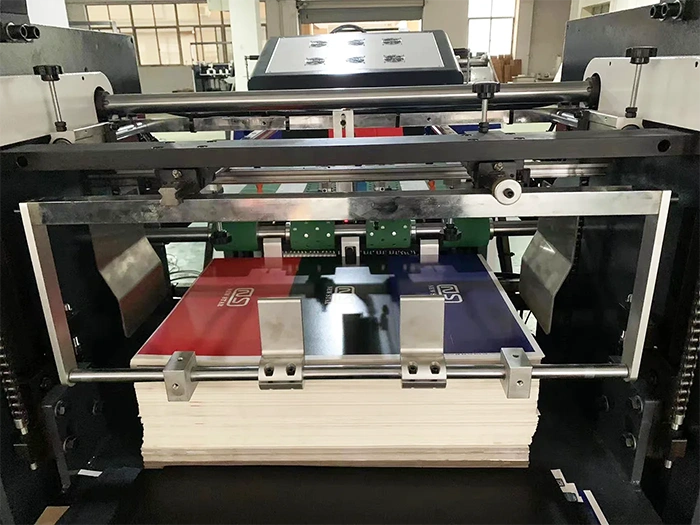

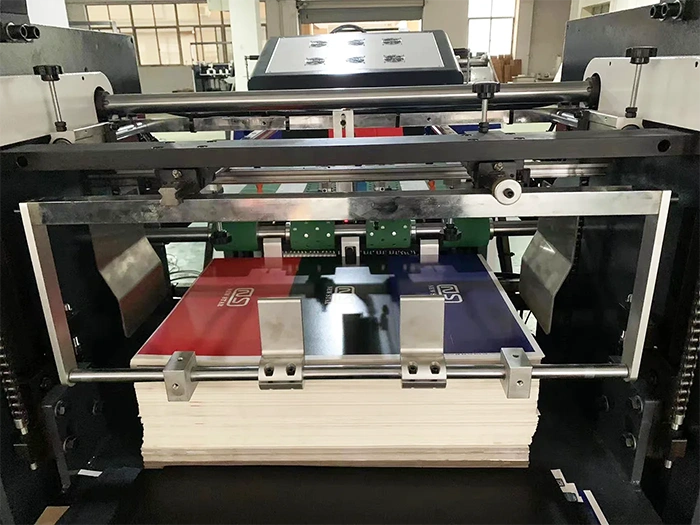

3: Use metering roller anilox roller to oil and then transfer to

blanket.

4: The closed scraper is used to circulate the oil inside without

outflow of oil, which can effectively reduce oil loss and

volatilization.

5: Equipped with 18 IR lamps and 3 UV lamps, which are controlled

separately.

6: Three roller design, tooth roller, plate roller, and anilox

roller. Stable and durable, suitable for water-based, oily, blister

oil, and uniform glazing effect.

(1) Auto feeding:

(2) Coating section (basic oil coating head):

(3) IR Drying and UV Curing System:

(4) Cooling system:

(5) Automatic delivery system:

FAQ:

1. What are your main products?

We Ecoographix is a specialized supplier of printing machines and

consumables. We cover both digital printing and offset printing,

including prepress, pressroom and post press, focusing on packaging

printing and book printing. We have hundreds of users all over the

world. We bring forward top quality of Chinese printing products to

meet diversified printing requirements.

2. What is your warranty?

Normally 1 year.

3. What is the Lead Time?

Usually 45 days and we will try our best to meet your demands.

4. What about the Installation and after-sales technician support?

Our engineer can go to help the installation and provide the

necessary training.

The buyer should take the round air plane tickets and service

charge and the local accommodation cost. Any problems or questions,

we will be at your disposal 7x24 hours.