Hangzhou Ecoographix Digital Technology Co., Ltd.

EcooGraphix is a leading global supplier and service provider for graphics

arts equipment and printing supplies. It started in 2010 with

developing and manufacturing CTP machines and printing plates.

EcooSetter CTP machines and Ecoo plates have now become well-known

brand names worldwide. There are over 500 printers worldwide

currently running EcooGraphix ctp and plates on daily base. There

are around 45 international distributors globally in partnership

with EcooGraphix. EcooGraphix teams have over 25 years' experience

specialized in prepress, printing, finishing equipment and

consumables and digital printing. We guarantee customer

satisfaction on every single product we provide.

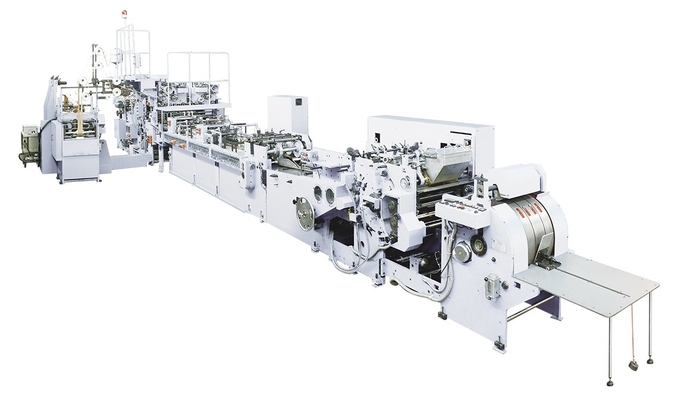

With extended product needs among our growing customer base as

well as major manufacturers partnership and support, EcooGraphix

has expanded its portfolio into additional printing supplies such

as offset printing inks, offset printing blankets, printing

chemicals, finishing equipment such as die cutting machines,

laminating machines, UV coating machine, digital cutter, book

binding machines, digital label printers, digital foil stamping

machines and 3D printers. Our goal is to provide customers with a

one stop shop for graphic arts equipment and supplies.

Understanding well international market requirements

and industry trends, EcooGraphix implements highest standard of

Quality control and production standard, allowing every product

meets the highest quality standard such as in USA, Canada, UK, and

Germany. Service is also at the core of EcooGraphix business. With

truly 7X24 hours worldwide service infrastructure and system,

EcooGraphix stands firmly behind every piece product and ensure

each customer of seamless operations.

Your Success, Our Destiny!