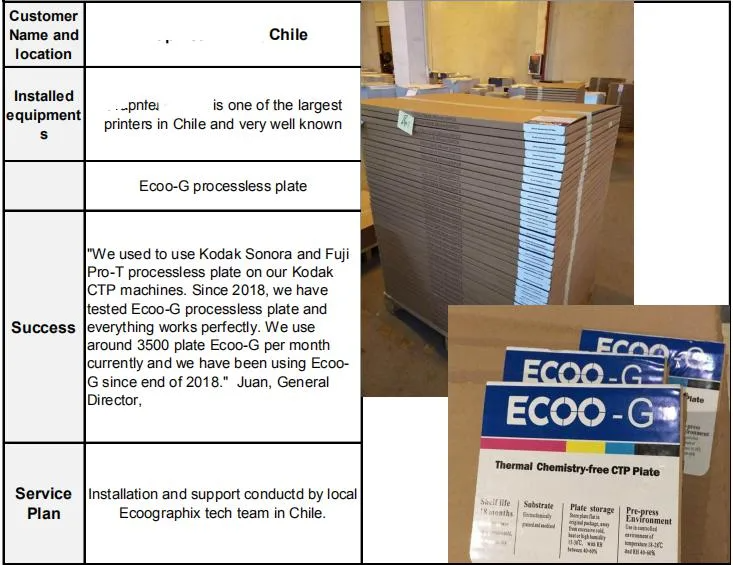

Product Description

1. INTRODUCTION OF ECOO-G

-Run length: 100,000 impressions

-Suitable for sheet-fed offset press or high speed rotary offset

press

-Suitable for different types of traditional inks and fountain

solutions, including alcohol's substitutes as fountain solutions

-Unsuitable to improve run length by baking plates

2. CHCARACTERISTIC OF ECOO-G

-Negative non-ablation photosensitive system

-Compatible with the dominant devices in the market

-Can be printed directly on the machine without any processing

steps after scanning by thermal CTP platesetter

-Good dot reproduction, stable performance, wide processing

latitude

-Long stability of latent image, can be stored at least a week

after plate-making

-High quality aluminum substrate, professional coating formulation

3. RECOMMENDES APPLICATION TO PRESS PROCEDURES OF ECOO-G

1. Clean all the inks on the blanket;

2. Start the press machine, apply the water roller, run 30-40

seconds;

3. Apply the ink rollers 20-30 seconds;

4. Apply the paper and start print.

Remark: If operate step 2 and 3 longer, paper will be wasted less.

Specification

Model ECOO-G

Plate Type

Thermal-negative type

Application

High grade commercial and newspaper printing

Substrate

Electrolyte graining and Anodized AL substrate

Thickness

0.15mm / 0.30mm

Maximum short grain width

Maximum width 1280 mm

Spectrum scope

800-850 nm

Photosensitive wave length

830 nm

Platesetter

Various dominant thermal platesetters in the market

Coating color

Grey

Low-energy imaging

130-150 mj/ cm²

The period of latent image stabilization

≤7 days

Recommended screen method

1-99% @200 LPI AM or 20μm FM or mixture

The paper number of start-up

<50 sheets

Safety light

4 hours under yellow light; 1 hour under fluorescent lamp;

Direct exposure under natural light is safe but not recommended.

Processing

Without processing, directly on press

Run Length

100,000 impressions Actual run length depends on printing

conditions

Shelf life

12 months under recommended condition

Transportation

Packed in seal and stored by means of prevention from light,

moisture, overheat and high humidity

Storage

Recommended condition: 18ºC-24ºC, 40%-50% RH.

| Model | Processless plate |

| Plate Type | Non-ablation thermal-negative type |

| Application | High grade commercial and newspaper printing |

| Substrate | Electrolyte graining and Anodized AL substrate |

| Thickness | 0.15mm / 0.30mm |

| Spectrum scope | 800-850nm |

| Platesetter | Various dominant thermal platesetters in the market |

| Low-energy imaging | 130-150 mj/ m² |

| The period of latent image stabilization | ≤7 days |

| Recommended screen method | 1-99% @200 LPI AM or 20μm FM or mixture |

| The paper number of start-up | <50 sheets |

| Safety light | 4 hours under yellow light; 1 hour under fluorescent lamp; Direct exposure under natural light is safe but not recommended. |

| Processing | Without processing, directly on press |

| Run Length | 100,000 impressions, actual run length depends on printing

conditions |

| Baking | No recommended |

| Maximum short grain width | Maximum width 1280 mm |

| Photosensitive wave length | 830 nm |

| Coating color | Grey |

| Shelf life | 12 months under recommended condition |

| Transportation | Packed in seal and stored by means of prevention from light,

moisture, overheat and high humidity |

| Storage | Recommended condition: 18ºC-24ºC, 40%-50% RH. |

Comparing With The Plate Of Kodak Sonora XP

| Features | ECOO-G | Kodak

Sonora XP |

| Sensitive wavelength(nm) | 800-850 | 800-850 |

| Coating color | Light green | Light green |

| Sensitivity (mj/cm2 ) | 150 | 150 |

| Exposure in safe light | White light 1 hour; yellow light 24 hours | White light 1 hour; yellow light 24 hours |

| After image contrast | Can be spotted by eyes,

but auto punching machine cannot recognize it | Can be spotted by eyes, but

auto punching machine cannot recognize it |

| Imaging device | Normal thermal CTP device 1-99% @ 200lpi | Normal thermal CTP device 1-99% @ 200lpi |

| Resolution | 1-99% @ 200lpi

(dependent on CTP capability) | 1-99% @ 200lpi

(dependent on CTP capability) |

| Run-length | 100,000 | 100,000 |

| Storage | 12 month (under recommend environment) | 12 month (under recommend environment) |

Applied parameters In Imaging Device

| Data | Kodak

trendsetters | LOTTEM

400(TH1.7) | MAGNUS 400 | Screen 8600S |

| Laser power | 15- 17W | 300-320mw | 19.5-21.5W | 80-90 % |

| Drum speed | 250-300rpm | 850-900rpm | 400-450rpm | 800-900rpm |

| Resolution | Customized | Customized | Customized | Customized |

| Parameter that | Focus/ | Focus/ | Focus/ | Focus/ |

| need set up | Zoom | Zoom | Zoom | Zoom |

Producing and Packing

From producing to delivery, we make every details very carefully to

guarantee the good product quality and service to customers.

Q1: Can I get the sample?

A: We are very glad to provide some sample for you to test. We

usually provide 5-15pieces plates for free,but sincerely hope to

get your kind support for the air courier freight. This cost can be returned to you in your first order.

Q2: What is the cost for the CTP plate sample freight?

A: The Air freight depends on the packing size and weight, and the

delivery destination. Or you can arrange the Pick-up service from

your local agent.

Q3: How long can the sample be ready?

A: It usually takes about 3days to prepare the sample.

Q4: Can I visit your factory?

A: You are warmly welcomed to visit our factory! Our company is in

Hangzhou city,which is about 1.5 hour by train from Shanghai.

Q5: How many Square Meters CTP plates can feed one 20' container?

A: About 20000-25000SQM