| Model | TDS790 |

| Max. Sheet Size(mm) | 790x560 |

| Min. Sheet Size(mm) | 310x210 |

| Max. Die Cutting Size(mm) | 760x520 |

| Max. Stamping Size(mm) | 760x525 |

| Inside Chase Size(mm) | 780x530 |

| Height Of Cutting Rules(mm) | 23.8 |

| Inter-platen Distance(mm) | 51.5 |

| Max. Pressure (N) | 120x104 |

| Stock Range | Min. Sheet 90g/m2, Cardboard 157-2000g/m2, E, B flute |

| Min. Gripper Margin(mm) | 6 |

| Max. Machine Speed(s/h) | 5500 |

| Max. Stamping Speed(s/h) | 5000 |

| The Thickness Of Stamping Plate(mm) | 5 (Optional 4+1) |

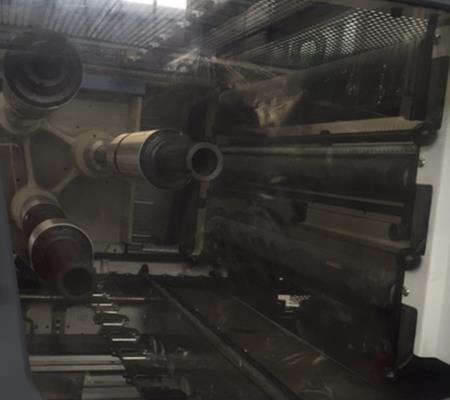

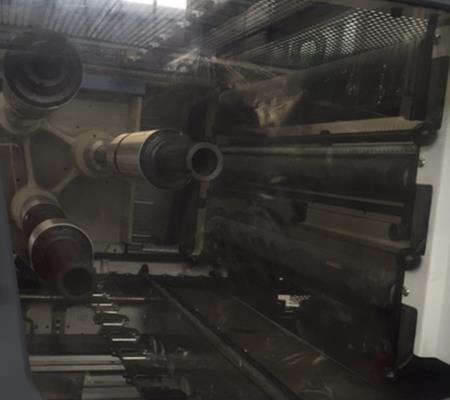

| Longitudinal Feeding Shafts | 3 |

| Transversal Feeding Shafts | 2 |

| Feeding Pile Height(mm) | 1200 |

| Delivery Pile Height(mm) | 950 |

| Electric Heating System | 8 zones |

| Min. Foil Width(mm) | 40 |

| Foil Reel Core(mm) | 25(1'') 76(3'') |

| Rated Power(kw) | 26 |

| Air Supply | 0.8-1.0MPa, ≥0.6m³/min |

| Overall Dimension(mm) | 3855 x 3650 x 2210 |

| Weight Of Machine(kg) | 8500 |

∷∷∷∷ Units of the Equipments ∷∷∷∷

♥ Feeding/ Delivery Unit

- Automatic feeder rolls back quickly to give easy access for make

ready and locks up in seconds

- One feeding bar for suitable paper infeed

- One delivery hand with 6 delivery fingers, adjustable according to

paper size

- Automatic elevated feeding pile

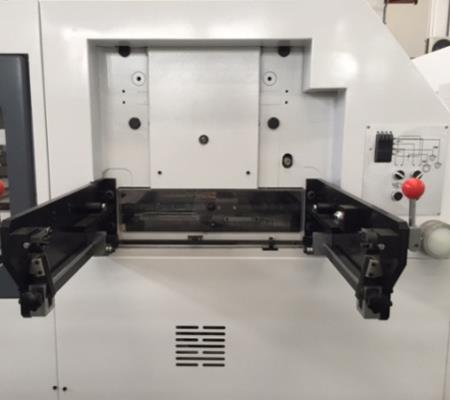

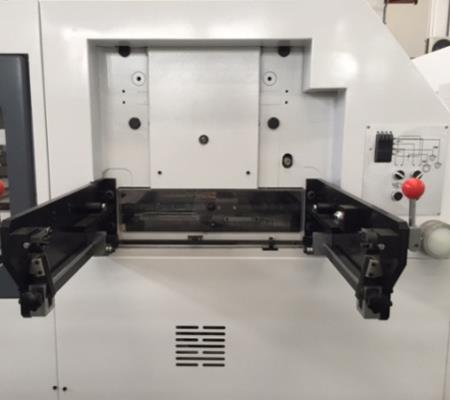

♠ Main Machine

- Delivers accurate, adjustable impression for foil stamping,

embossing and die cutting

- Two horizontal, cross pull foil feeds are fully programmable to

provide maximum versatility and excellent foil economy

- Air blast system helps to separate foil from stock on critical jobs

- Micrometer adjustment on side guide and front guide

- Adjustable dwell on impression

- Honeycomb base is convenient for loading

- Missed sheet detector

- 4 heating zones with digital control

- 24 hours preheating device

- Control system with touch screen HMI, PLC and servo system

- Videos on Youtube: https://youtu.be/7CTccHcRUIc

∷∷∷∷ Advantages ∷∷∷∷

• Transmission of main unit adopt imported A/C frequency converter

control, start up and stop of the machine are controlled by means

of imported air clutch.

• Running of the whole machine is controlled by PLC. Interface

touch-screen for monitoring machine running condition, trouble

indications and their corresponding shooting ways. This is more

operator-friendly.

• Independent temperature control to each heating zone makes

operation temperature of the machine more equal and stable.

Function of timing preheating can enhance working efficiency

greatly.

∷∷∷∷ Producing And Packaging ∷∷∷∷

From producing to delivery, we make every details very carefully to

guarantee the good product quality and service to customers.

∷∷∷∷ Certificates ∷∷∷∷

∷∷∷∷ FAQ ∷∷∷∷

Q1: What are your main products ?

A: Our main products are the Prepress 4up and 8up Online/Offline

Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates,

Offset Inks, Offset Printing Blankets, Postpress Packing Equipment

and so on.

You can get the equipment and consumables all in one and no worry

about the after-sales service from our company.

Q2: Where is your factory ?

A: Our CTP processor machine factory is in Shanghai, you are warmly

welcome to visit our factory!

Q3: Is there any certification for your CTP processor ?

A: Yes, all our machines have been certified by SGS and CE.

Q4: Can you also supply the Workflow and RIP ?

A: Yes, we can provide the Workflow Brainnew and RIP Compose V12.

Q5: What about the installation and after-sales technician support

?

A: Our engineer can go to help the installation and provide the

necessary training. The buyer should take the round air plane

tickets, service charge and the local accommodation cost. Any

problems or questions, we will be at your disposal 7x24 hours.

Among our large amount of CTP installations worldwide, there are

also many end users(printers) who have purchased the CTP products

from EcooGraphix China directly and EcooGraphix technical service

team support these installations remotely with regular onsite

visits.

These end users printers all run the CTP systems with full

satisfaction due to our robust quality, seamless remote service,

thorough training and maintanence. If you are a printer who is

considering purchasing directly from EcooGraphix China, there is no

hassle on installations, training and after sales service. We

guarantee your satisfaction.

Video ☞ https://youtu.be/7CTccHcRUIc