TD 1650S Automatic Corrugated Die-Cutting Machine

With Stripping

. ∷ . ∷ . ∷ . ∷ . Brief Introduction . ∷ . ∷ . ∷ . ∷ .

TD 1650S automatic corrugated die cutting machine has two kinds of

feeder: lead edge fed feeder and bottom suction feeder. Each feeder

meets different paper.

. ∷ . ∷ . ∷ . ∷ . Details . ∷ . ∷ . ∷ . ∷ .

♥ Friction Feeder

Friction feeder brings strength and high accuracy. Equipped with

high-pressure sucking unit.

Feeding belt is controlled by servo or mechanical system depend on

different material, which is more stable.

♦ Bottom-fed with Suction Feeder

Equipped with Japanese design bottom-fed non-stop feeder with 6

suckers. Scratches created on the paper during feeding can be

avoid.

Equipped with reliable paper feeding, front lay and double-sheet

sensor.

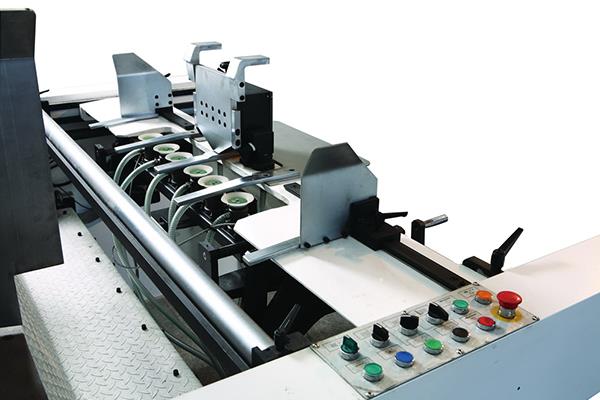

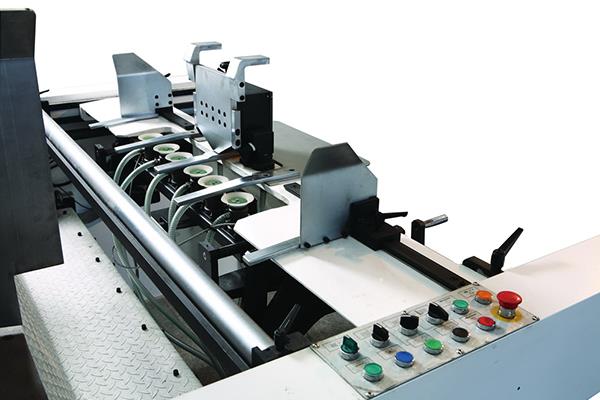

♣ Stripping Section

Double-action movement structure with upper and lower stripping

frame facilitates die change, motorized upper frame suspending

hoistsystem for easy installation. Male/female die are available

for different stripping.

♠ Die Cutting Section

Pressure can be set on the touch screen. The machine supervision

display and 3d touch screen show the working conditon of the

machine for malfunction diagnosis. Chase is installed with

centerline system and pneumatic lock-up system.

. ∷ . ∷ . ∷ . ∷ . Specifications . ∷ . ∷ . ∷ . ∷ .

Model

TD 1650S(Lead edge fed feeder)

Max. Sheet Size (mm)

1650 x 1200

Min. Sheet Size (mm)

650 x 520

Max. Die-Cutting Size (mm)

1630 x 1180

Inside Chase Size (mm)

1660 x 1215

Min. Gripper Margin (mm)

6

Min. Gripper Waste (mm)

12mm(distance from first knife to paper edge)

Max. Die Cutting Pressure

400tons

Corrugated Paper (mm)

2 - 9

Max. Machine Speed (s/h)

5000

Die Cutting Plate Size (mm)

1680 x 1186

Cutting Knife Height (mm)

23.8

Main Motor Power

22Kw

Total Power

40Kw

Voltage

380/220V, 3PH, 50/60HZ

Dimension (incl. platform)

(L)10255 x (W)5469 x (H)2500mm

Weight

38tons

Model

TD1650S(Bottom suction feeder)

Max. Sheet Size (mm)

1650 x 1200

Min. Sheet Size (mm)

650 x 520

Max. Die-Cutting Size (mm)

1630 x 1180

Inside Chase Size (mm)

1660 x 1215

Min. Gripper Margin (mm)

6

Min. Gripper Waste (mm)

12mm(distance from first knife to paper edge)

Max. Die Cutting Pressure

400tons

Corrugated Paper (mm)

2-9

Max. Machine Speed (s/h)

5000

Die Cutting Plate Size (mm)

1680 x 1186

Cutting Knife Height (mm)

23.8

Main Motor Power

22Kw

Total Power

45Kw

Voltage

380/220V, 3PH, 50/60HZ

Dimension (incl. platform)

(L)11130 x (W)6000 x (H)2564mm

Weight

38tons

| Model | TD 1650S (Lead edge fed feeder) | TD 1650S (Bottom suction feeder) |

| Max. Sheet Size (mm) | 1650 x 1200 | 1650 x 1200 |

| Min. Sheet Size (mm) | 650 x 520 | 650 x 520 |

| Max. Die-Cutting Size (mm) | 1630 x 1180 | 1630 x 1180 |

| Inside Chase Size (mm) | 1660 x 1215 | 1660 x 1215 |

| Min. Gripper Margin (mm) | 6 | 6 |

| Min. Gripper Waste (mm) | 12mm(distance from first knife to paper edge) | 12mm(distance from first knife to paper edge) |

| Max. Die Cutting Pressure | 400tons | 400tons |

| Corrugated Paper (mm) | 2 - 9 | 2 - 9 |

| Max. Machine Speed (s/h) | 5000 | 5000 |

| Die Cutting Plate Size (mm) | 1680 x 1186 | 1680 x 1186 |

| Cutting Knife Height (mm) | 23.8 | 23.8 |

| Main Motor Power | 22Kw | 22Kw |

| Total Power | 40Kw | 45Kw |

| Voltage | 380/220V, 3PH, 50/60HZ | 380/220V, 3PH, 50/60HZ |

| Dimension (incl. platform) | (L)10255 x (W)5469 x (H)2500mm | (L)11130 x (W)6000 x (H)2564mm |

| Weight | 38tons | 38tons |

. ∷ . ∷ . ∷ . ∷ . Application . ∷ . ∷ . ∷ . ∷ .

Automatic corrugated die cutting machine also named as corrugated box die

cutting machine, mostly uses to cut thick corrugated for package of

TV, air conditioner, washing machine and so on.

. ∷ . ∷ . ∷ . ∷ . Producing And Packaging . ∷ . ∷ . ∷ . ∷ .

From producing to delivery, we make every details very carefully to

guarantee the good product quality and service to customers.

. ∷ . ∷ . ∷ . ∷ . Certification . ∷ . ∷ . ∷ . ∷ .

. ∷ . ∷ . ∷ . ∷ . FAQ . ∷ . ∷ . ∷ . ∷ .

Q1: What are your main products ?

A: Our main products are the Prepress 4up and 8up Online/Offline

Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates,

Offset Inks, Offset Printing Blankets, Postpress Packing Equipment

and so on.

You can get the equipment and consumables all in one and no worry

about the after-sales service from our company.

Q2: Where is your factory ?

A: Our CTP Processor machine factory is in Shanghai, you are warmly

welcome to visit our factory!

Q3: Is there any certification for your CTP processor ?

A: Yes, all our machines have been certified by SGS and CE.

Q4: Can you also supply the Workflow and RIP ?

A: Yes, we can provide the Workflow Brainnew and RIP Compose V12.

Q5: What about the installation and after-sales technician support

?

A: Our engineer can go to help the installation and provide the

necessary training. The buyer should take the round air plane

tickets, service charge and the local accommodation cost. Any

problems or questions, we will be at your disposal 7x24 hours. Among our large amount of CTP installations worldwide, there are

also many end users(printers) who have purchased the CTP products

from EcooGraphix China directly and EcooGraphix technical service

team support these installations remotely with regular onsite

visits.

These end users printers all run the CTP systems with full

satisfaction due to our robust quality, seamless remote service,

thorough training and maintanence. If you are a printer who is

considering purchasing directly from EcooGraphix China, there is no

hassle on installations, training and after sales service. We

guarantee your satisfaction.

. ∷ . ∷ . ∷ . ∷ . www.ecoographix.com . ∷ . ∷ . ∷ . ∷ .